Assembly Machines

Assembly Machines

Body

| - manual, semi-automatic, automatic |

| - single and multi-stations |

| - shuttles and/or rotary indexers to transfer parts nests between stations |

| - pneumatic or servo linear manipulators to transfer sub-assemblies between stations |

| - equiped with the sensors and/or cameras for parts/process verification and vision inspection |

| - compact layout to minimize production floor space usage |

| - ergonomically friendly for operator interaction with the machine |

| - multiple assembly technologies (Ultrasonic staking & welding, Infra-red staking & welding, Clip, Gromet, Pushnut installation/assembly, Screw driving, etc.) |

| - can be equipped with bowl feeders for automatic component loading |

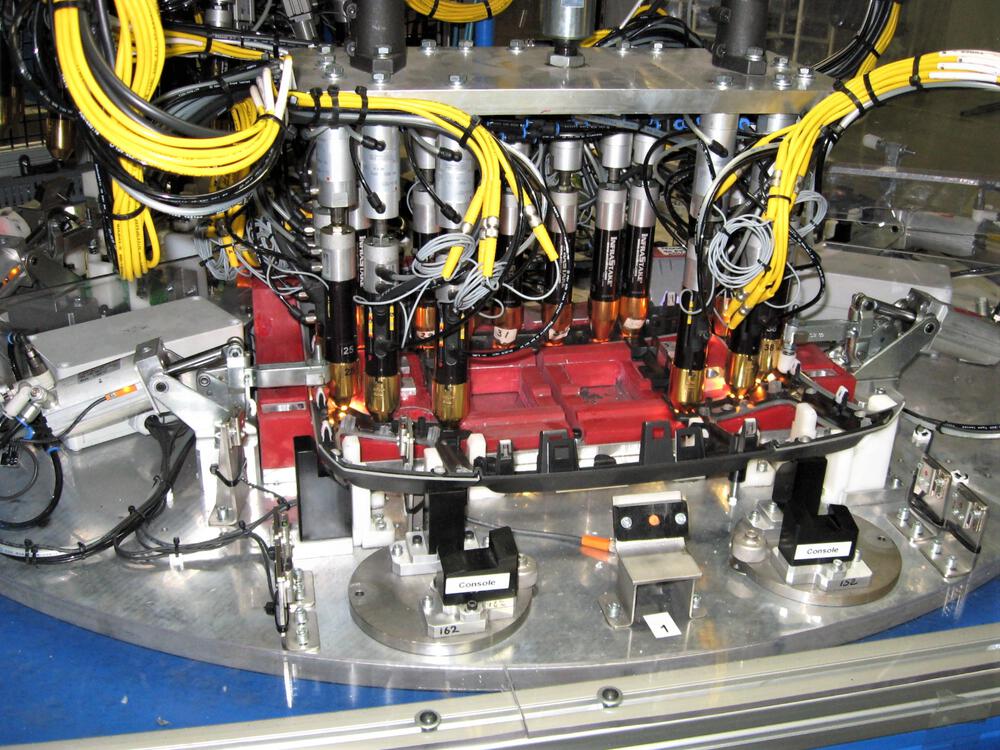

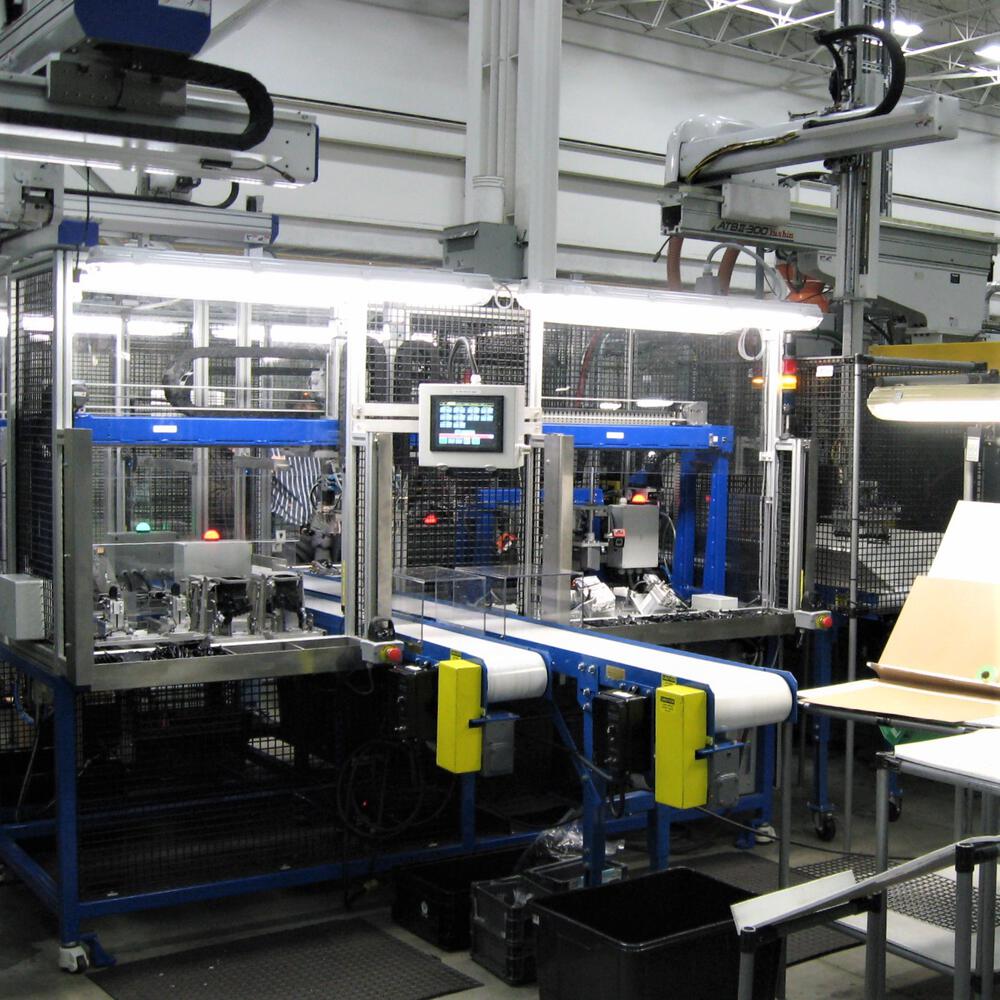

Automatic Assembly System - Car Air Registers Assembly - Multi Stations

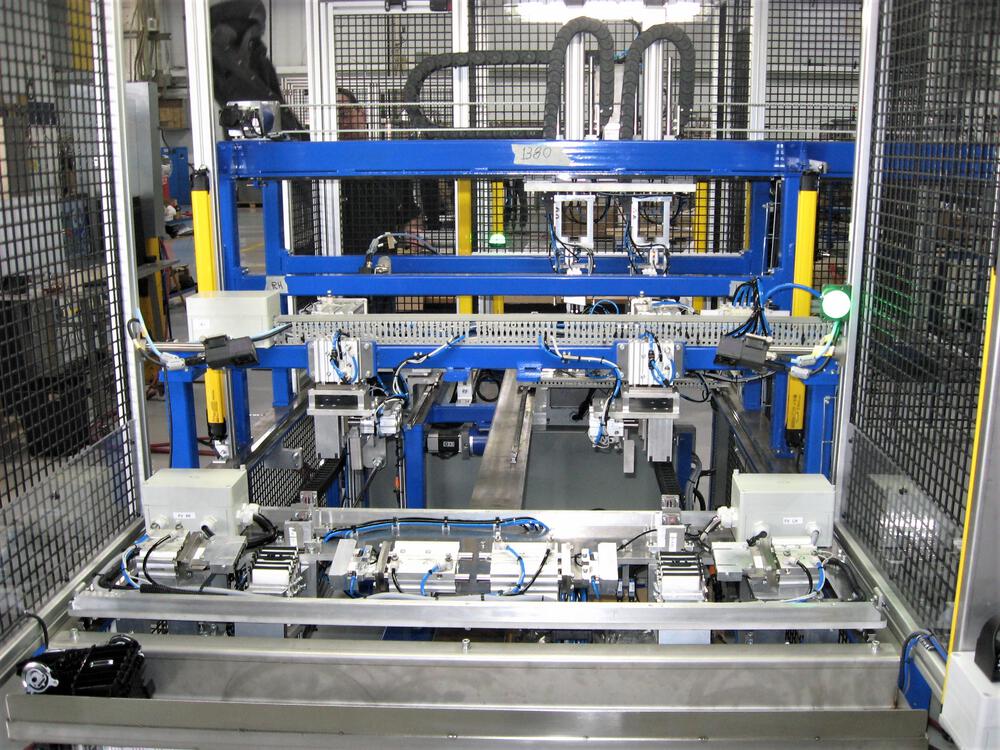

Automatic Assembly System - Car Air Registers Assembly - Servo Shuttle Tables

Automatic Assembly Fixture - Rotary Indexer, Infra-red staking

Automatic Assembly Fixture - Two Servo Shuttle Tables, Ultrasonic welding

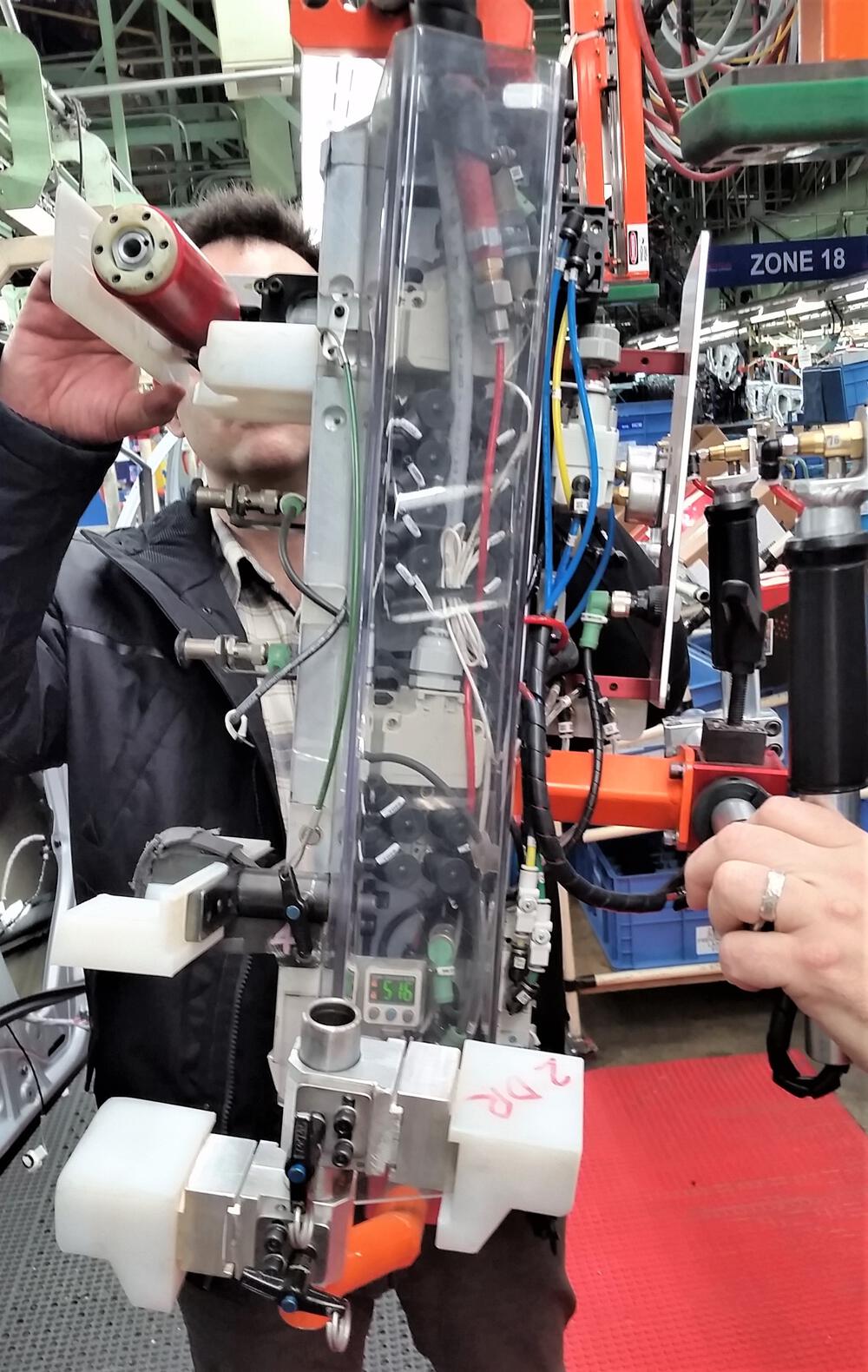

Semi-automatic Assembly Fixture - Car Front Door Garnish assist assembly

Semi-automatic Assembly Fixtures - Car Air Box Assembly

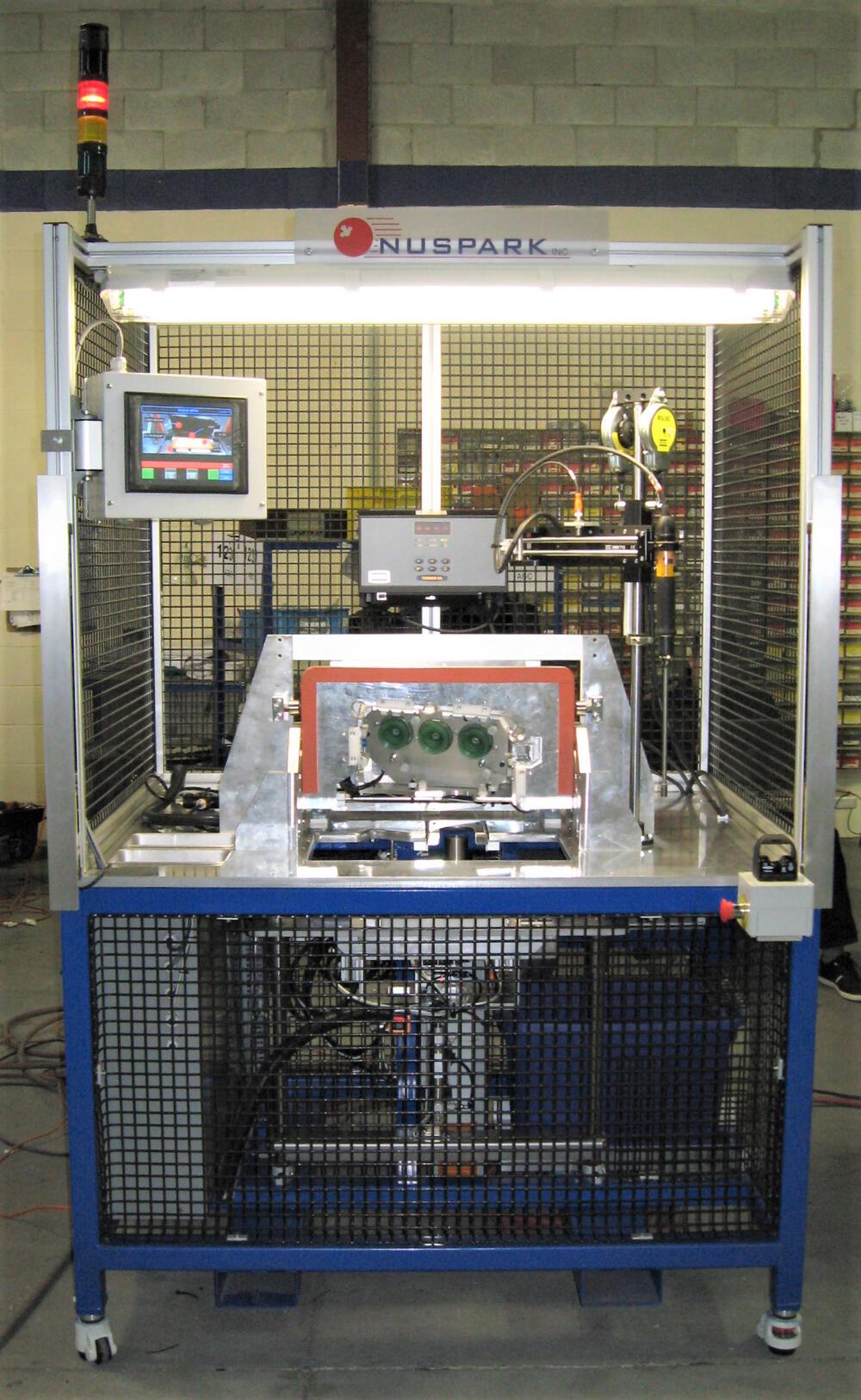

Automatic Assembly Fixture - Duct Inlet Ultrasonic Welding Fixture

Robotic Cell - Duct snapping, Compression limiter assembly I rubber gromet

Robotic Cell: Ultrasonic and Infra Red Assembly, Label Application

Semi-automatic Assembly System - Gizmo Single Cap

Semi-automatic Assembly System - Furniture Drawer