Automation solutions to maximize your production

Nuspark designs and builds versatile, practical packaging and automation equipment for customers in the food, pharmaceutical, personal care, consumer goods and automotive markets.

We convert complex engineering design into flexible, real world solutions.

We specialize in cartoning, case packing, palletizing, automotive assembly fixtures, and custom engineered solutions.

1000+ Installations

4 Continents

15 Countries

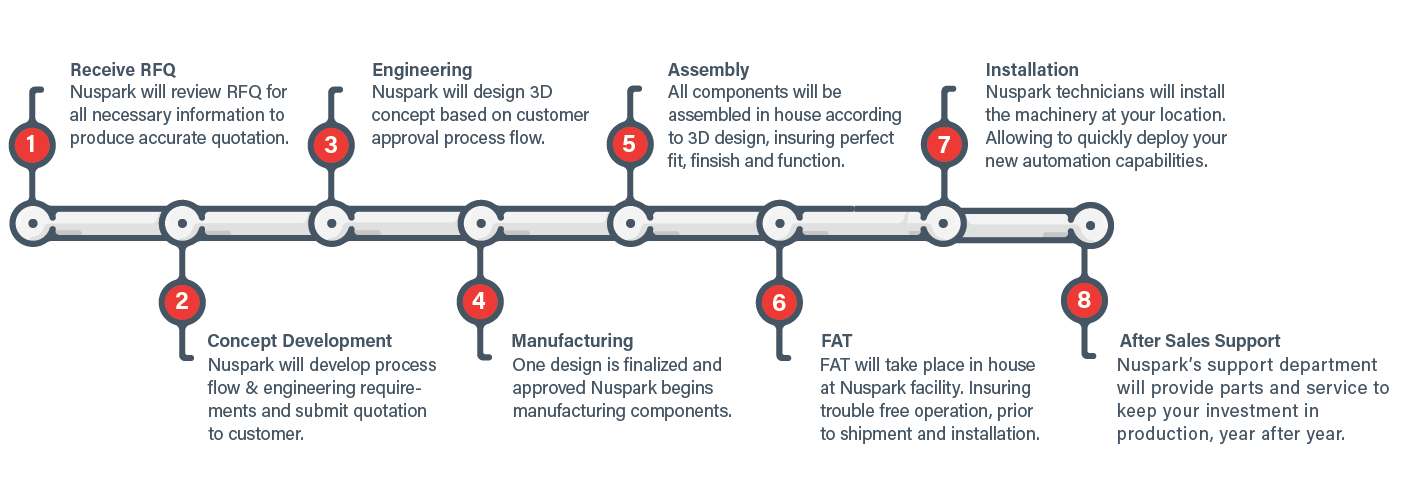

Our process in detail

Customer Needs Evaluation & Feasibility Review

Nuspark begins every design project by evaluating your existing capabilities and discussing your automation goals.

-

If your manufacturing is not yet automated, we’ll recommend machinery requirements, the amount of machinery you’ll need within your limits of healthy ROI. We’ll uncover and recommend packaging changes to better suit automation. In this way, we insure, best return on your investment.

If your manufacturing is not yet automated, we’ll recommend machinery requirements, the amount of machinery you’ll need within your limits of healthy ROI. We’ll uncover and recommend packaging changes to better suit automation. In this way, we insure, best return on your investment.

-

If your manufacturing is automated, we’ll look for and recommend enhancements to your existing system that will improve your foot-print and add savings. We’ll measure your current product offering sizes as well as cases and pallets

If your manufacturing is automated, we’ll look for and recommend enhancements to your existing system that will improve your foot-print and add savings. We’ll measure your current product offering sizes as well as cases and pallets

Our customer needs evaluation and feasibility review includes

-

Determining the number and variety of machines needed to accommodate your operations.

Determining the number and variety of machines needed to accommodate your operations.

-

Assessing adequacy of your existing floor space.

Assessing adequacy of your existing floor space.

-

Recommending “best-fit” possibilities and an accurate speed for optimal automation.

Recommending “best-fit” possibilities and an accurate speed for optimal automation.

-

Proposing where automation may be ill-advised (low speed, high complexity).

Proposing where automation may be ill-advised (low speed, high complexity).

-

Through experience we have learned that at times, it is better to stay with a manual system if it is complex and slow.

Through experience we have learned that at times, it is better to stay with a manual system if it is complex and slow.

Engineering and Concept Development

Our design team, made up of PhD’s and mechanical engineers, creates inventive (innovative), practical designs to meet your process specifications and manufacturing requirements.

Nuspark Inc. will:

Use 3-D software for full visualization of your manufacturing system prior to the build

Use 3-D software for full visualization of your manufacturing system prior to the build Offer multiple design reviews with feedback loops prior to system build

Offer multiple design reviews with feedback loops prior to system build Customize off-the-shelf equipment and machines – with proven solutions that we apply to your environment

Customize off-the-shelf equipment and machines – with proven solutions that we apply to your environment Build prototypes and then validate each automated system

Build prototypes and then validate each automated system

Manufacturing and Assembly

Nuspark’s engineering management team oversees the manufacturing and assembly of your system.

Only Canadian-made parts

Modular systems to fit your floor space

Modular systems to fit your floor space Laser cut and water jet technology

Laser cut and water jet technology CNC machining

CNC machining In-house welding with medical-grade, stainless steel

In-house welding with medical-grade, stainless steel All systems pass a Factory Acceptance Test (FAT)

All systems pass a Factory Acceptance Test (FAT)

Service, Installation and After-sales Support

Nuspark Inc. provides full service for all systems and equipment we design and build. We offer

Full installation

Full installation Assistance or take-over of integrated line assemblies for customers

Assistance or take-over of integrated line assemblies for customers After sales support

After sales support

Hands-on Customer Training: Training at our facility

You will receive training either on the floor with your new machine or in a modern, fully equipped training room (for classroom sessions).

Training at your plant

Where feasible, you can be trained onsite. Nuspark Inc. offers classroom and hands on training for new installations or for refresher courses.

Training includes operation, mechanical and electrical troubleshooting, machine adjustments and setups and machine changeovers.

Customer Needs Evaluation & Feasibility Review

Nuspark begins every design project by evaluating your existing capabilities and discussing your automation goals.

- If your manufacturing is not yet automated, we’ll recommend machinery requirements, the amount of machinery you’ll need within your limits of healthy ROI. We’ll uncover and recommend packaging changes to better suit automation. In this way, we insure, best return on your investment.

- If your manufacturing is automated, we’ll look for and recommend enhancements to your existing system that will improve your foot-print and add savings. We’ll measure your current product offering sizes as well as cases and pallets

Our customer needs evaluation and feasibility review includes

- Determining the number and variety of machines needed to accommodate your operations.

- Assessing adequacy of your existing floor space.

- Recommending “best-fit” possibilities and an accurate speed for optimal automation.

- Proposing where automation may be ill-advised (low speed, high complexity).

- Through experience we have learned that at times, it is better to stay with a manual system if it is complex and slow.

Engineering and Concept Development

Our design team, made up of PhD’s and mechanical engineers, creates inventive (innovative), practical designs to meet your process specifications and manufacturing requirements.

Nuspark Inc. will:

Use 3-D software for full visualization of your manufacturing system prior to the build

Offer multiple design reviews with feedback loops prior to system build

Offer multiple design reviews with feedback loops prior to system build Customize off-the-shelf equipment and machines – with proven solutions that we apply to your environment

Customize off-the-shelf equipment and machines – with proven solutions that we apply to your environment Build prototypes and then validate each automated system

Build prototypes and then validate each automated system

Manufacturing and Assembly

Nuspark’s engineering management team oversees the manufacturing and assembly of your system.

Only Canadian-made parts

Modular systems to fit your floor space

Modular systems to fit your floor space Laser cut and water jet technology

Laser cut and water jet technology CNC machining

CNC machining In-house welding with medical-grade, stainless steel

In-house welding with medical-grade, stainless steel All systems pass a Factory Acceptance Test (FAT)

All systems pass a Factory Acceptance Test (FAT)

Service, Installation and After-sales Support

Nuspark Inc. provides full service for all systems and equipment we design and build. We offer

Full installation

Full installation Assistance or take-over of integrated line assemblies for customers

Assistance or take-over of integrated line assemblies for customers After sales support

After sales support

Hands-on Customer Training: Training at our facility

You will receive training either on the floor with your new machine or in a modern, fully equipped training room (for classroom sessions).

Training at your plant

Where feasible, you can be trained onsite. Nuspark Inc. offers classroom and hands on training for new installations or for refresher courses.

Training includes operation, mechanical and electrical troubleshooting, machine adjustments and setups and machine changeovers.

Nuspark’s Success & Commitment

Nuspark’s Success & Commitment

Before every system design, we listen carefully to your specific needs; your budget, your timeline, your unique challenges and parameters. We find solutions that optimize your output, reduce your downtime, and increase efficiencies.

Nuspark’s management team is comprised of gifted, highly-educated engineers with over 50 years engineering/robotics experience and 30+ patents to our name.

We value our reputation for creative innovation. We maintain this reputation through constant analysis of new and emerging technologies, ensuring that our customers benefit from state-of-the-art-design and construction.

Comprehensive in-house capabilities delivers effective troubleshooting support and machine retrofitting. Nuspark’ facilities include:

- In-house mechanical engineering

- In-house electrical controls & panel design/assembly

- In-house machine shop

- Programmers for AB, ELAU, Omron and Siemens

- In-house welding

We are strategically located in Toronto from where we serve all major North American markets.

Whether your requirement is for a custom engineered solution or one of the many standard and proven automation platforms available, Nuspark delivers packaging and automation solutions that perform in the real world.